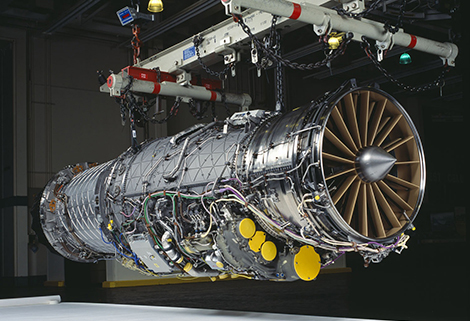

SCENARIO 3

Direct delivery of parts from the supplier in Japan to Amendola (Italy) to ensure Aircraft Availability status for the Italian Air Force.

The SSC-CC has conducted a daily review of the current and anticipated availability of the Italian F-35 unit at Amendola airbase. The flight planning of the next couple of months shows an increase compared to baseline flying profile due to increased (international) training out of Amendola.

Local stock levels might be insufficient to guarantee the F-35’s availability. A temporary increase of local stock of parts SHOCK STRUT ASSEMBLY LMLG and SHOCK STRUCT ASSEMBLY are chosen by the SSC-CC to resolve this potential issue.

The SSC-CC has established that there is no excess stock present within the EMEA region, the SSC-CC requests extra parts stock for SHOCK STRUT ASSEMBLY LMLG and SHOCK STRUCT ASSEMBLY from the (global) item manager.

The item manager has ordered these parts directly from the Japanese supplier to resupply the local stock at air force base Amendola to ensure future aircraft availability (AVA) status. The item manager chose to place the procurement order by himself due to price and serialized items.

These parts are received by the freight forwarder at Rome Airport constituting the point of entry into Europe.

The goods are delivered to the bonded warehouse at the airbase and conditionally assigned to the unit to prevent re(al)location to other orders without being noticed by the SSC-CC. Goods remain customs goods to enable this re(al)location if needed, up to the moment the goods are definitively issued to an Italian aircraft work order.

for the F-35 sustainment program

-

SCENARIO 1Addition of a new partner country to the Europea F-35 region

-

SCENARIO 2Daily planning run to replenish central warehouse inventories from the US supply base

-

SCENARIO 3Direct delivery of parts from Japan to Italy to ensure Aircraft Availability

-

SCENARIO 4F-35 aircraft AOG, delivering a part to air base Germany on Sunday

-

SCENARIO 5F-35 crypto part is exported to from the Regional Warehouse

-

SCENARIO 6Optimization of the distribution of supplies across the EU network

-

SCENARIO 7Spare part redistributed from Ørland (Norway) to Volkel (Netherlands)

-

SCENARIO 8Redistribute a part (ITAR) stocked at UK aircraft carrier to US carrier in Tunis harbor

-

SCENARIO 9Repair of defective part at repair vendor takes longer than expected

-

SCENARIO 10A repair vendor faces a problem with SRC availability

-

SCENARIO 11Grouping of shipments from different sources

-

SCENARIO 12A regular demand is upgraded to an Aircraft on Ground (AOG) situation.

-

SCENARIO 13Deployment spare part package (DSP)

-

SCENARIO 14An urgent service bulletin for the F35 fleet and with a short due date is issued.

-

SCENARIO 15A new OEM supplier and parts are introduced into the F-35 Supply Chain